Enhanced Oil Recovery

- Home

- Enhanced Oil Recovery

Enhanced Oil Recovery

Physical basis of the EHT technology

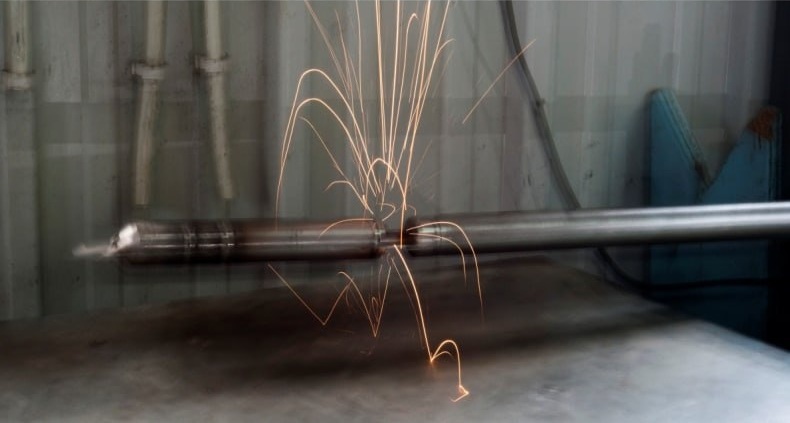

The EHT technology is based on the occurrence of a high-voltage electric discharge between electrodes in a liquid. When an electric discharge occurs between two electrodes in a liquid, energy is released within a short period. A powerful high-voltage electrical pulse (3000-

5000 V) generates ultrahigh pulsed hydraulic pressures, as well as acoustic and electromagnetic radiation across a wide range of frequencies, including X-rays, and cavitation phenomena. During the discharge, energy is released, transitioning into a state of highly heated gas at very high pressure, which, in turn, exerts a significant force on the surrounding environment, causing its movement.

When a shock wave propagates through a solid elastic medium, the shock front dissipates relatively quickly, and the shock wave transforms into a series of successive oscillations propagating at the speed of elastic waves. The release of energy places alternating loads on the bottom-hole zone of the formation and the formation itself. With multiple repetitions of the

‘compression – decompression’ cycles, hydraulic shock pressure waves propagate through the formation’s framework and its porous medium, enhancing the capacitive and filtration properties of the rocks in the near-wellbore zone. Under their influence, the perforation intervals are cleaned of sediments, colmating rock particles, and asphalt-paraffin deposits within the formation. The pressure impulses open natural fractures in the reservoir and facilitate the formation of new fractures.

Operation of the EHT technology equipment

The downhole tool acts on the formation with

controlled periodic fluctuations as a result of

creating an explosive effect in the liquid between the electrodes, while creating a gas “bubble” of high initial pressure and temperature, which penetrates into the formation through perforation channels in

the form of a shock wave.

Alternating effects on the reservoir create microcracks, change the filtration and capacitance properties and reduce the viscosity of oil, increasing the permeability of productive formations and the inclusion of poorly drained reservoir zones in the work, reducing the water content of products.

The EHT technology can be used in workover wells.

The processing time and the number of pulses of impact on the formation is determined by the

geological features of the productive formation and takes 6-18 hours, depending on the capacity of the reservoir and the number of productive reservoirs.

The downhole tool is lowered into the well on a three-core cable. The cable is used to power downhole equipment, control the operation of the deep block, control the operating mode of the equipment and the parameters of well processing.